About Refrigeration

We also need to make sure that we have enough reclaim and recovery. It’s very important to recover as much of the older HFCs like R-410A as possible, so that way we have an adequate supply of reclaim moving into the future years and making sure that no one is forced to replace any equipment early due to a lack of supply.

Please contact us by email below and we will respond shortly

Refrigeration, the process of removing heat from an enclosed space or from a substance for the purpose of lowering the temperature.

In the industrialized nations and affluent regions in the developing world, refrigeration is chiefly used to store foodstuffs at low temperatures, thus inhibiting the destructive action of bacteria, yeast, and mold. Many perishable products can be frozen, permitting them to be kept for months and even years with little loss in nutrition or flavour or change in appearance. Air-conditioning, the use of refrigeration for comfort cooling, has also become widespread in more developed nations. Before mechanical refrigeration systems were introduced, ancient peoples, including the Greeks and Romans, cooled their food with ice transported from the mountains. Wealthy families made use of snow cellars, pits that were dug into the ground and insulated with wood and straw, to store the ice. In this manner, packed snow and ice could be preserved for months. Stored ice was the principal means of refrigeration until the beginning of the 20th century, and it is still used in some areas.

Just a little insight into refrigeration and coolers. Enjoy!

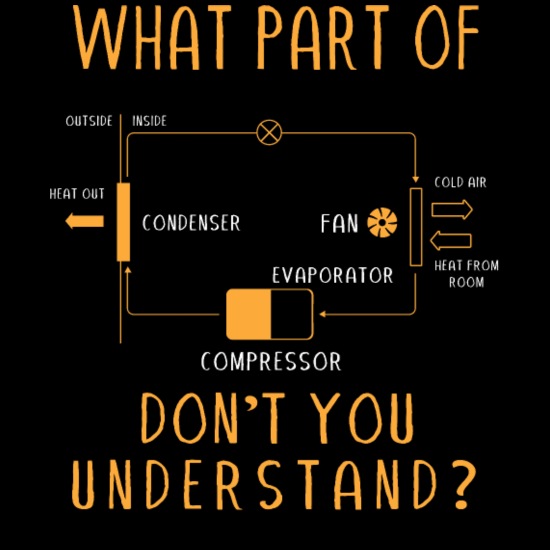

The Refrigeration Cycle is a simple but amazingly clever and useful process.

In its simplest form, the refrigeration cycle consists of just 4 basic components to complete the circuit:

- A Compressor

- A Condenser

- A Restriction

- An Evaporator

That’s it. Well, that’s almost it – we also need a refrigerant to cycle inside the circuit.

As the name suggests, the refrigeration process is a cycle.

We start at the compressor, go through the condenser, then through the restriction, then through the evaporator and finally back to the compressor where the cycle starts all over again.

So let’s have a brief look at each of the components in turn. Luckily, their names are quite self explanatory:

1. The Compressor.

The Compressor can be thought of as the heart of the process.

It acts like a pump to create the circulation by compressing the refrigerant gas, creating a pressure difference that drives the refrigerant around the circuit in a continuous cycle.

2. The Condenser.

The Condenser cools and condenses the refrigerant gas coming from the compressor in to a vapour and finally in to a liquid.

3. The Restriction.

The restriction restricts the liquid refrigerant flow and creates a pressure difference between itself and the evaporator. The restriction is more commonly referred to as a METERING DEVICE as it meters the amount of refrigerant entering the evaporator.

4. The Evaporator.

The Evaporator evaporates the liquid refrigerant in to a vapour and then in to a gas before it gets back to the compressor.

5. The Refrigerant.

You may have noticed that in this very brief and simplified introduction to the components, that we have already talked about the refrigerant being a GAS, VAPOUR and a LIQUID. It is this changing of state within the refrigerant that produces the refrigeration effect, and is the main principle of the refrigeration cycle – more on this a bit later.

Source: https://www.torr-engineering.com/the-refrigeration-cycle/

Could Propane Be the Secret to Greener Air Conditioning?

Hot summer days are often a welcomed sight. However, temperature records are being broken worldwide, which experts say is being fueled by the climate crisis and poses a significant risk to human and planetary health as well as the future of the planet.

Moreover, as the days get hotter and hotter, the use of air conditioning systems will likely rise, which is a threat to the environment due to their high energy consumption and increased warming potential of the refrigerants used.

A recent study led by the International Institute for Applied Systems Analysis (IIASA), Austria, however, suggests that the secret to greener air conditioning could lie in using propane, a clean-burning alternative fuel, as a refrigerant.

The study published in Proceedings of the National Academy of Sciences of the United States of America (PNAS) was led by Pallav Purohit of the IIASA together with the United Nations Environment Programme and researchers from the University of Leeds.

Propane exhibits significant environmental advantages through good energy performance and a global warming potential of less than 1. In split-ACs up to 7 kW, propane can be classified as a technically valid alternative to HFC-driven split-ACs.

Pallav Purohit, IIASA

The team demonstrated that by using propane as an alternate coolant in air conditioning systems, there is the potential to prevent a 0.09 °C increase in global temperature, which could mean keeping any future rise in global temperature below 1.5 °C.

Adopting Propane

While energy-efficient propane-based air conditioning systems are being rolled out in Chinese and Indian markets, a lift on current bans and regulations would be required to see a global adoption of propane as an alternate refrigerant.

Methods are being developed to use blended HFCs with lower GWP. Using the IIASA GAIN model, Purohit and his team were able to report that this would reduce greenhouse gas emissions from split-ACs by around 44% by the year 2100.

However, using propane, this figure doubled to a reduction of around 88% in the same period.

Source: https://www.azocleantech.com/news.aspx?newsID=32134

The Role Of Businesses In Creating More Environmentally Friendly Cooling Systems

Forbes Councils Member

COUNCIL POST| Membership (Fee-Based)

With 2023 bringing a record heat wave to Texas, along with the worst fire season in Canada’s recent history (causing unprecedented air pollution in NYC and beyond), many experts have drawn a correlation between extreme weather and global warming.

As the founder and CEO of a company that offers a cooling intelligence platform, one of the ironies of today’s fight against climate change I’ve noticed is the negative feedback loop that underlies so many drivers of global warming. This destructive, self-reinforcing cycle is perhaps nowhere more apparent than in the cooling sector. In warmer weather, we need more cooling—refrigeration and air conditioning (AC)—than ever. Yet these technologies are contributors to global warming.

PROMOTED

Like many bellwethers of modern economic development, this “cooling crisis” reflects a central tension of our generation: How do we improve human health without damaging our planet’s health?

Our Cooling Crisis

How often do you think about your refrigerator or air conditioner? Mostly, they’re left on in the background and keep us well-fed and comfortable. For the better part of a century, cooling has largely worked in the same way. We purchase a piece of equipment, plug it into the wall, and don’t think about it again—until it breaks or needs replacing.

At the same time, refrigeration and AC can contribute to climate change in three ways: food waste, refrigerant leaks and energy use.

Despite its massive carbon footprint, research suggests that demand for cooling is growing. According to a Center for Global Development report (via The Guardian), most of the population is expected to move out of extreme poverty by 2050, and with the standard of living rising for these individuals, people are likely to desire greater comfort in their living and working spaces; want more fresh food than ever before; and seek access to temperature-sensitive vaccines and pharmaceuticals. Shifts like these should be celebrated—they reflect an expansion of human well-being.

But new expectations and consumption would require an increase in cooling capabilities. The refrigeration and AC sectors are poised for rapid growth if what exists today no longer suffices in the future. At the height of the Covid-19 pandemic, the AP reported that nearly 3 billion people lived in areas where “temperature-controlled storage is insufficient for an immunization campaign to bring COVID-19 under control.” A few years ago, The Guardian noted that AC power consumption is expected to grow 33 times by 2100 due to urbanization and the rise of developing world incomes.

We should celebrate when people around the world gain access to better food and pharmaceuticals (refrigeration), as well as greater comfort and convenience (AC). Yet, in the face of such inarguable progress, cooling is already responsible for nearly 10% of global emissions, according to one estimate (via the BBC). If warming accelerates the need for more cooling, this negative feedback loop could get worse in the decades ahead.

We need greater awareness—and rapid innovation—to turn vicious cycles of development into virtuous ones. To do so, it’s important to first understand how cooling causes warming.

Food Waste

Inadequate or faulty cooling causes significant food waste, as equipment issues force businesses to throw out perishable products. According to 2013 estimates from the International Institute of Refrigeration, 13% of food is lost due to lack of refrigeration; put another way, an improved cold chain could feed 950 million people per year. And this waste could cause tremendous warming—if it were a country, one report estimates that food waste would have been the third largest emitter of CO2 equivalent in 2013.

Refrigerant Leaks

Project Drawdown has identified refrigerant management as the top currently available climate mitigation practice. These chemical compounds make refrigeration and AC possible, yet chlorofluorocarbons (CFCs)—a class of chemical refrigerants—“can produce more than 10,000 times as much warming [as CO2], pound for pound, once they are in the air,” according to MIT News. One kilogram of the refrigerant R410a has the same greenhouse effect as two tons of carbon dioxide or running your car for six months. In the U.S., we permit businesses to leak up to 30% of refrigerants from industrial process refrigeration before they have a duty to repair their equipment.

Energy Use

Beyond the ultra-warming effect of refrigerants, cooling uses enormous amounts of energy. AC and electric fans alone account for nearly one-fifth of all electricity consumed in buildings globally, according to a 2018 IEA report.

Cooling already uses a ton of energy. (Well, technically, it emits over 100 million metric tons of CO2 into the air each year.) And energy use increases on hot summer days as systems have to work overtime. This overtaxing of electricity grids contributes to the use of dirty and expensive “peaker plants,” which amplify the carbon footprint of cooling.

Cooling Intelligence

As the saying goes, “Necessity is the mother of invention.” Our cooling crisis is a thumbnail sketch of a larger challenge: Businesses need to develop smarter and more sustainable ways of delivering goods and services and supporting modern life.

There are many possibilities. Cooling today is mostly “dumb”—not connected to the cloud or optimized with data science. Users leave a piece of equipment running uninterrupted for years, resulting in blind energy consumption. Imagine a world in which refrigerators and air conditioners learned to power up or down based on utilization (for example, automatically turning off when schools are closed for holidays). Or they could provide extra cooling during times of the day when electricity is cheaper and cleaner and run slightly warmer when that power is expensive and dirty. (Full disclosure: My company offers a platform with some of these capabilities.)

Transforming cooling into intelligent batteries and developing cleaner refrigerants that have less of a warming effect are additional solutions to explore.

While innovators are developing smarter and more sustainable cooling solutions, both cost and inertia represent key challenges to adoption. To transform the status quo, they will need to ensure companies see savings on their energy and equipment bills with their solutions. It’s important to ensure clean cooling solutions deliver financial ROI without sacrificing comfort or convenience. And with new climate-positive tax incentives through state and federal programs such the Inflation Reduction Act (IRA), the math is likely to get better each year.

Ultimately, the “cooling crisis” is just a microcosm of our broader climate crisis: They require that we mobilize innovation and ingenuity to advance human health while protecting the planet’s health.

Source Forbes magazine :

posted without permission

Forbes Magazine article https://www.forbes.com/sites/forbesbusinesscouncil/2023/07/14/the-role-of-businesses-in-creating-more-environmentally-friendly-cooling-systems/?sh=27a8455c6126

NEWSREFRIGERATIONSTANDARDS AND LEGISLATIONREFRIGERANTS

The Refrigerant Transition Picks Up the Pace in 2023

Industry experts offer their views on the state of refrigerants this year

January 24, 2023

The HVACR industry is undergoing another refrigerant transition, as HFCs such as R-410A and R-404A are being phased down in favor of new, lower-GWP refrigerants, such as R-32 and R-454B. Unlike the last transition, which shifted from the use of one nonflammable (A1) refrigerant to another, many of these new refrigerants are mildly flammable (A2L), so additional care will need to be taken in order to safely use them.

This year will also be pivotal for the refrigerant transition, as a 40% reduction in HFC production occurs starting January 1, 2024. Below, industry experts offer advice about what contractors need to know about the transition, as well as how to prepare for it.

EXPERT OPINIONS

Alex Ayers, director of government affairs at HARDI

The AIM Act that was passed in 2020 phases down the production and consumption of HFCs, including all the major refrigerants that we use today in air conditioning and refrigeration. That means that 2023 is really an important year for us to prepare for this transition, as 2024 is our first major reduction in production of HFCs. With that reduction in HFC refrigerants, we’re going to need to prepare for this next generation of refrigerants that will come into play. And that means A2Ls or mildly flammable refrigerants will start being used in air conditioning equipment very soon.

For contractors and distributors, this means making sure that you are trained on A2L refrigerants, whether that is from a third party or from your equipment manufacturer. Distributors also need to prepare to receive bulk shipments of A2L cylinders, along with precharged equipment. It’s really important for everyone to spend 2023 preparing, whether that is going through training or getting your updated occupancy permits for your warehouses, making sure that you understand what’s going to be required of you as this transition goes on.

That’s going to be partially accelerated by the changing state of building codes, where more and more states are adopting A2Ls earlier than what was maybe expected a couple of years ago. This ensures that we have enough places to install A2Ls for that first major step down.

Source for this article

https://www.achrnews.com/articles/147515-the-refrigerant-transition-picks-up-the-pace-in-2023